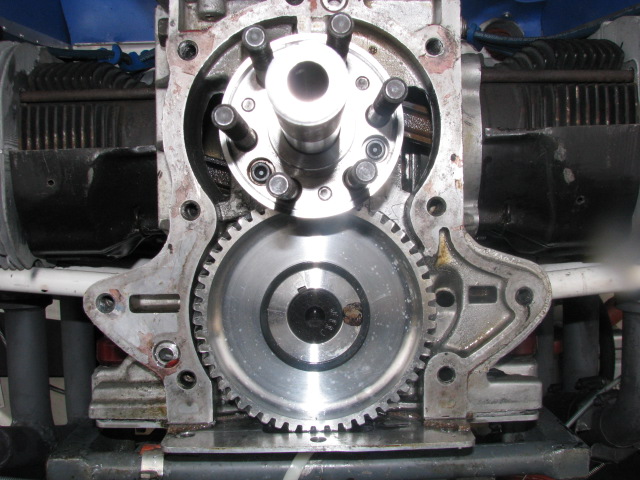

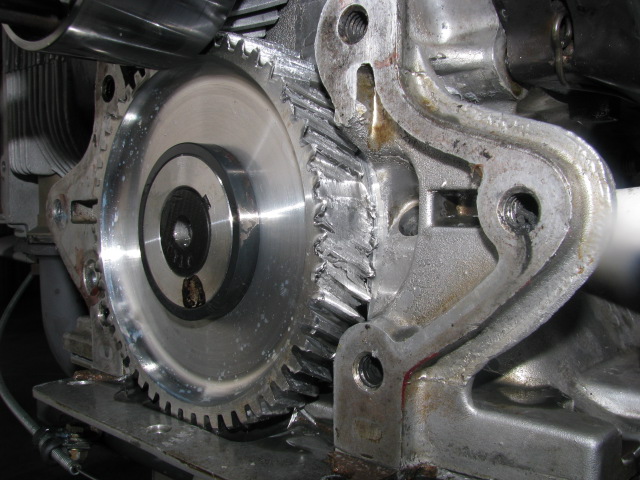

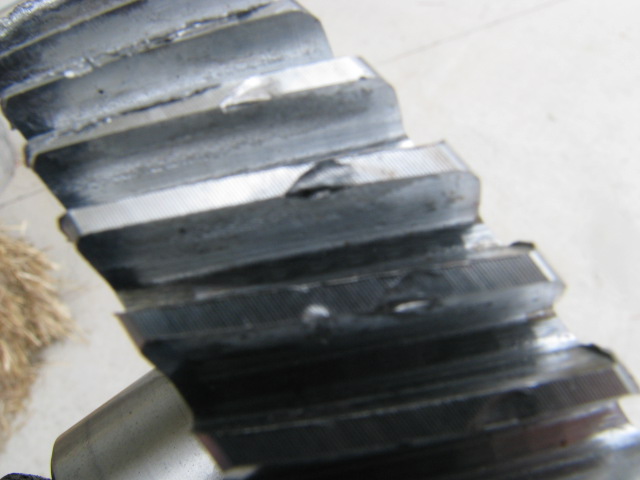

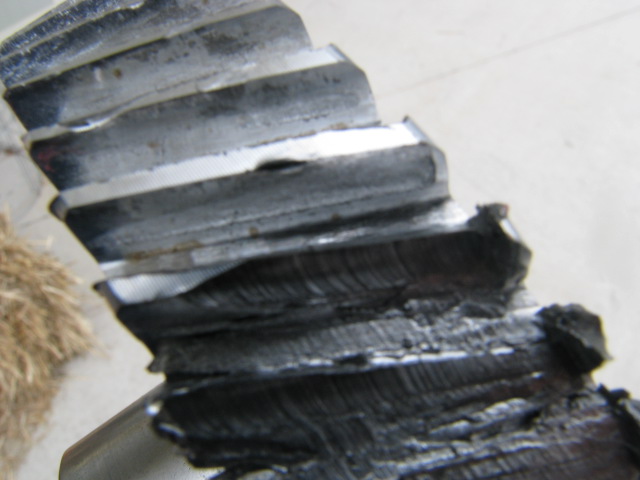

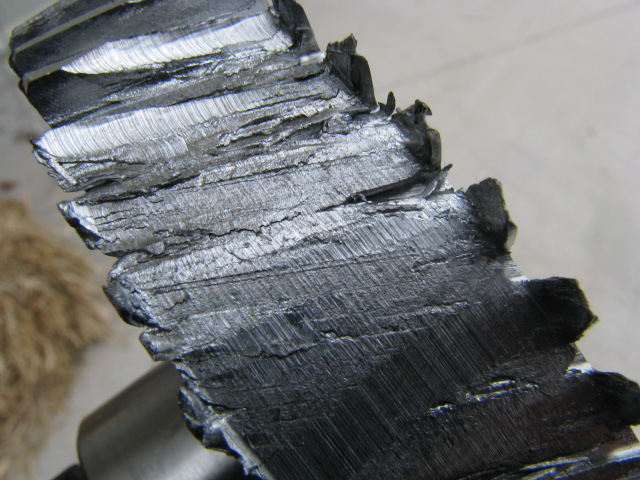

As most of you are aware of, back on 8-16-08 my crankshaft broke as I was doing a cross country flight. That broken crank resulted in a complete rebuild of my Corvair engine. I spared no costs in doing this rebuild as I wanted this to be the last time that I had an engine failure. The gear on my OT-10 cam had acquired some damage when the crank broke so I sent my cam to Clark's to have them install a new "failsafe" cam gear. While I was at the 2008 KR Gathering, Clark's called and said my OT-10 cam lobes were marginal and I should replace the cam. Well, I bought a brand new OT-10 cam with a new "failsafe" gear installed. I also purchased a fifth bearing and installed that on my Corvair engine. I was feeling very good and excited about this rebuild. The first flight after rebuilding the engine occured on 10-12-08 and needless to say, I was very excited in the engine performance. I made seven more short flights after that first one which resulted in a total of 4.5 hours on the newly rebuilt engine when the "failsafe" cam gear failed. It was on 11-1-08 when I was crusing at 5000' at a distance of 4.5 miles from KSTE airport when I had a sudden engine out. However, I actually thought at first that the engine was still running because it was turning 1500 rpm. Fortunately, STE was almost straight ahead and I had a straight in approach to the airport. I could not get the engine to respond to anything I did and that is when I realized it was windmilling and not actually running. There were several planes around STE and one had just called in for a touch and go and another called holding short for takeoff. I was now 3.5 miles out and that was when I called in for all aircraft to clear the runways as I had an engine out and needed the airport. I also announced my position and intentions at that time. Immediately everyone that was in the vicinity and on the ground replied and stated they were clearing the area for me. "Fly the plane, fly the plane", kept going through my head and I stayed calm. The airport called a couple of times asking my position and did I want a crash crew called. I told them negative on the emergency response team as I knew I had the airport made. Fortunately as I approcahed final for runway 03, I had plenty of altitude and actually had to make a couple of S turns to bleed off altitude. I did not deploy my speeed brake because I wanted to keep my speed up so I would not have to worry about getting too slow. I crossed the numbers doing about 90, touched down at 70 and coasted off the first taxiway. It was a picture perfect landing. The airport manager met met on the taxi way and we towed her back to the hangar. In the photos below, you can see that I apparantly had a gear tooth failure which resulted in the crankshaft gear eating away several teeth. The reason I think a tooth failed is because once I rotated the cam gear to engage the crank gear, everything turned freely. So, do we now have another point of failure on the Corvair engine? I would say so since this is the second cam gear failure I know of since last July. Unfortunately, the bearing and hub in my fifth bearing sustained damage from all the aluminum floating through the oil system and I am sure the main bearings and rod bearings are shot too. The bottom two photos were taken after I rotated the cam shaft.

Update 11/3/2008. The crank gear was causing wear on 180° of the cam gear teeth. Beginning exactly with the tooth with the timing mark stamped on it, you can see a wear pattern starting to develop. With each progressive tooth for 180° to the point of failure, the teeth wear became more pronounced until the final teeth were like a knife edge. This led to the breaking of the tooth and grinding away the following few teeth. So, what does this tell us? Was the gear run out bad? The remaining 180° of teeth exhibited little to no wear

Update 11/6/2008. I have determined today, with a dial indicator, that the cam gear is cocked on the on the cam shaft. I mounted the dial indicator where it would measure the run out of the face of the cam gear. This was done by placing the indicator tip on the forward lip just under the teeth on the gear. From the absolute lowest point and rotating the cam, I got a run out of .017 inch. A closer visual inspection of the shaft protrusion through the gear hub clearly indicates that the gear is cocked as the edge of the camshaft is not even in relation to the edge of the gear hub.